Steam power was one of the most significant developments of the Industrial Revolution (1760-1840) in Britain. First invented as a pump in the 1690s, a host of inventors tweaked designs and tinkered with machinery until an efficient and powerful alternative to muscle, water, and wind power attracted commercial users. Through the 19th century, the steam engine revolutionised industry and travel, bringing benefits and challenges in equal measure.

Harnessing Steam Power

Before the Industrial Revolution, large machines were powered by water wheels, animals, or humans. All three were relatively expensive (at least in Britain). These power sources worked well, and water wheels best of all, but the obvious necessity of a water source was a limitation. Water wheels could also malfunction in cold conditions. One industry, in particular, needed a new technology to perform better. This was coal mining. The mining of coal had always been limited by the fact that the deeper the shafts, the more groundwater flooded in and prevented the extraction of coal. What was needed was a powerful machine pump. By 1700, Britain produced 80% of the coal in Europe. The coal mines were big business, and it was this fact that moved investors and inventors to find a cheap solution to flooded mines so that more coal could be extracted. This is why the steam engine, although using theories of scientists across Europe, was invented in Britain.

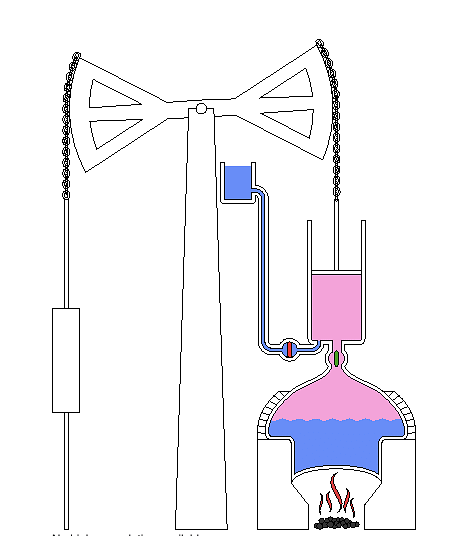

The power of steam was first harnessed for a pump by Thomas Savery (c. 1650-1715), patented in 1698, but its power was limited. The first important principle is that heated water produces steam which is 1500 times more voluminous. The steam, when it cools and condenses back to water, then dramatically reduces in volume and creates a partial vacuum. The vacuum creates a power of suction, which can be used to suck in water. In scientific terms, it was discovered that the weight of the outside atmosphere, with its higher pressure than the vacuum in the machine, creates an energy force which can be used to move something from one place to another.

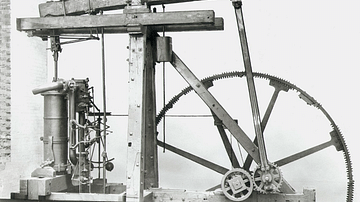

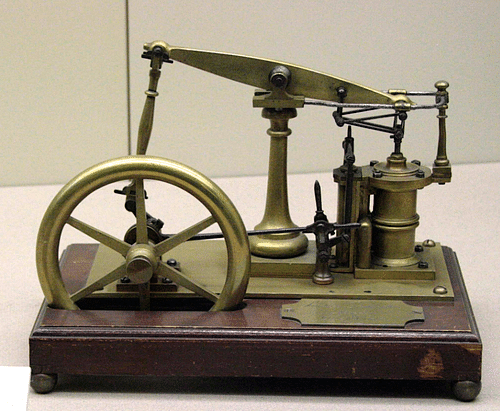

The principles of vacuums and atmospheric pressure were known in the 17th century by such scientists as Galileo (1564-1642) and Evangelista Torricelli (1608-1647), but the problem was building an engine apparatus strong enough to resist the pressures involved. If the pressure could be harnessed and increased, it could be used to suck in a piston, not just water as Savery's steam pump had done. The downward movement of the piston into the vacuum is a power stroke that can be used to raise a levered beam. Just like a seesaw, the piston goes down and the attached beam goes up. The rising beam can then lift another piece of machinery. When the vacuum tank is emptied using valves to let out the steam, the beam falls back to its natural position thanks to gravity, and so the piston is pulled back out of the vacuum tank, ready to repeat the cycle.

In 1710, Thomas Newcomen (1664-1729), an ironmonger in Dartmouth, found the way forward by adjusting Savery's design, essentially increasing the speed of the condensation process (by injecting cold water), and so the power. Another key innovation was that instead of using a straight piston rod (which could easily jam if bent slightly), a chain was used. Newcomen's steam engine pump was first used in a coal mine in Dudley in the Midlands in 1712. The machine could suck 5,000 gallons (22.7 K litres) every hour out of a 153-foot (46.6 metres) deep mine shaft. Newcomen's 'atmospheric engine' was not very efficient in terms of the coal required to heat it, but as it operated in coal mines, that was not a problem. To use such a machine elsewhere and not be prohibitively expensive would need some more engineering tweaks.

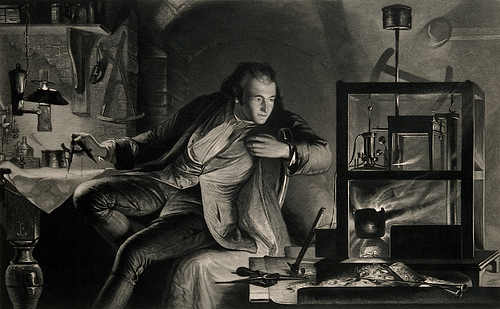

The efficiency of the early steam engines was improved thanks to the Scottish instrument maker James Watt (1736-1819) in 1769 and again in 1778 with the help of Matthew Boulton (1728-1809). Watt separated the hot and cool parts of the machinery which were interfering with the efficiency of the condensing action. His machine is, therefore, often called the separate condenser. Watt also made sure steam pushed the piston down at the same time as the vacuum pulled it in, thus increasing the power (measured in 'horsepower', a term coined by Watt). Watt then called upon the skills of John and William Wilkinson, who were expert cannon makers. The Wilkinson boys could provide Watt's steam engine with much better iron parts, which ensured very little steam escaped by accident from the piston mechanism. Watt kept on tinkering with his machine until he reached the point where his steam engine used only a quarter of the coal Newcomen's had. Now steam pumps could be used in tin and copper mines where coal was expensive.

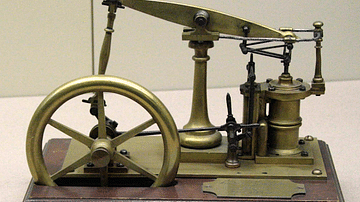

Steam engines kept on evolving. An important improvement was the expansion engine, which essentially shut off the heat source before the steam had fully expanded, allowing the expansion to continue naturally and thus saving on fuel. Controlling the steam expansion using valves was another step forward. Even better was the design to make the power stroke a circular one (rotary motion), which could power a flywheel, much more versatile than a straight rod or chain and much more stable. With developments in materials and the input of other designers, who often shared their findings, it became possible by 1800 to harness only the steam part of the process and not worry about the condensing part. More powerful but using much less fuel and so much cheaper to run than ever before, steam engines could now be used virtually anywhere.

The steam engine came in all sizes and was now an extraordinarily complex piece of machinery. In the curious mutual aid of the Industrial Revolution, machines were used to improve other machines so that steam engines powered cutting and metalworking machines to produce better and stronger parts that could be used for the steam engines yet to come. By 1800, Britain boasted over 2,500 steam engines, most of them used in mines, cotton mills, and manufacturing factories. These engines fed on coal and, as a consequence of their success, coal mining boomed. Steam engines were also now being used in coal mines in other European countries, notably Belgium, France, Germany, and the Netherlands.

Through the 19th century, the presence of machines everywhere meant that refinements were made by those who worked with them on a daily basis. In 1845, William McNaught, for example, greatly increased the pressure and so power of his machines. This evolution eventually culminated in the first steam turbine, which converted the energy into a wheel with thin blades like a giant fan. It was invented in 1884 by Charles Parsons (1854-1931) who used it to power his ship Turbina to an astonishing speed of 34.5 knots. By 1907, there were well over 9.5 million steam-powered machines in Britain. This was the end of the evolution of the steam engine before the combustion engine and electricity took over as the main power sources. Through the 19th century, though, steam power had travelled a long way from the coal mines and found a whole range of uses across every major industry.

Steam Trains

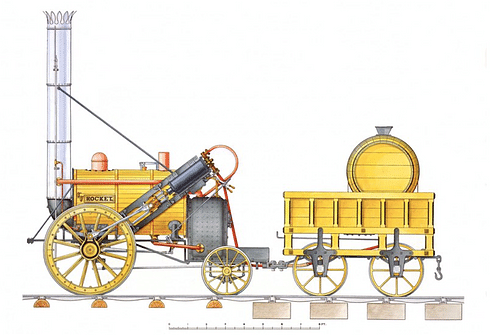

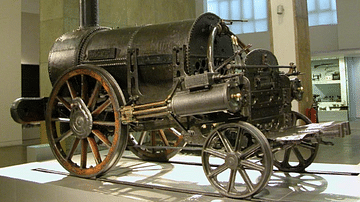

The canal system in Britain had long been the best way to transport goods from one place to another, but their domination was about to be challenged by a cheaper and much faster alternative: the railways. In 1801, the first steam-powered road vehicle was invented by Richard Trevithick (1771-1833) following his development of the high-pressure steam engine (low-pressure engines simply did not have the necessary power to drive vehicles). His machine was very good but let down by the poor quality of the roads available. In 1803, Trevithick invented the first steam railway engine which could run on its own purpose-built tracks. On 27 September 1825, the Locomotion 1 train invented by George Stephenson (1781-1848) transported the first railway passengers from Stockton to Darlington in the northeast of England. In 1829, George Stephenson's son, Robert Stephenson (1803-1859), created the Rocket, and he entered it in the Rainhill Trials. The Trials were competitions designed to find the best locomotive for use on the new railway line planned to connect Manchester to Liverpool and which opened in 1830. In 1838, Birmingham was connected to London; in 1841, passengers could take the train from the capital to Bristol. The railways were booming.

The iron tracks spread so quickly across Britain, the phenomena became known as 'railway mania'. By 1870, there were over 15,000 miles (24,000 km) of rail lines. For many destinations, no longer did passengers have to brave the slow and uncomfortable horse-drawn carriages that had previously been the only means of travelling long distances. Speed and comfort were now the expectations of travellers.

Steam-Powered Ships

Steam and transportation seemed made for each other. Ship design was another area revolutionised by the arrival of the steam engine, but there was a fundamental problem. As a steam engine needed a huge amount of coal and pure freshwater (which does not damage the mechanisms) to operate, any ship powered using a steam-driven paddle wheel needed to devote a large proportion of its load capacity to these essentials. For these reasons, early steam-powered boats tended to be small affairs and limited to short trips, usually along rivers. What was needed for long-distance steam ships was even more efficient engines, and so the engineers got to work. Yet again, necessity drove invention. The new steam engines now captured wasted exhaust steam and included multiple pistons or cranks. This increase in power and efficiency meant less fuel was needed and the dominance of sail could finally be challenged.

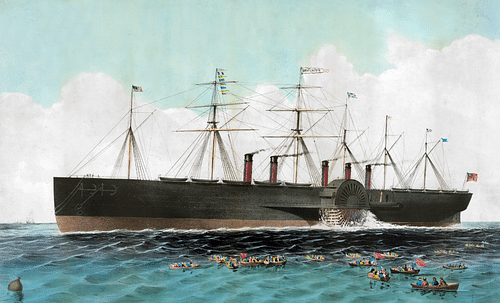

The first steam-powered ferry was the Hibernia, which carried passengers between Holyhead in Wales and Dublin in Ireland. Steam-powered ships were simultaneously developed in other countries, particularly in the United States for travelling along the Ohio and Mississippi Rivers from 1811. Bigger ships came along and even crossed the Atlantic, but the problem of space for the engines and coal still meant there was not much room left for cargo or passengers. Consequently, these early ships were not commercially viable. Long-distance sea voyages were simply too expensive because of the fuel costs. A rethink on just how big a ship should be was necessary.

The great engineer Isambard Kingdom Brunel (1806-1859) used a steam engine to power his giant ships the SS Great Western (1838), the innovative propellor-driven SS Great Britain (1843), and the SS Great Eastern, the largest ship in the world at 692 feet (211 m) long and completed in 1858. These ships and others crossed the Atlantic faster than ever before (10 days compared to 32 using just sail), and soon ambitious new routes to India and Australia were established. The first cargo ship using steam power was the John Bowes, built in 1852.

The age of sail, at least for large ships, was coming to an end. Steamships were not dependent on the wind and could travel in a straight line (sail ships have to tack against a headwind), decreasing the length of voyages. Speed became the new priority of ocean travellers. The quicker and cheaper access steamships gave to new resources and consumer markets worldwide drove on industry to produce ever more goods, which, in turn, led to the production of yet more steam-powered machines.

Steam-Powered Machines

By 1789, steam-powered cotton looms were in use in textile factories, a machine first invented by Edmund Cartwright between 1784 and 1786 and first used effectively in factories owned by the cotton baron Richard Arkwright (1732-1792). Cartwright's machine doubled the speed of production but was not all that efficient; subsequent inventors worked on this problem with success. By 1835, around 75% of cotton mills were using steam power. A steam-powered factory did not need to be located near a water source, and so better sites could be chosen where there were more people and natural resources, like coal, were close by.

Sewage pumps used steam power, town fountains did, too, and so did engines that cleared waterlogged areas to make them useful for agriculture. Coins were now minted by steam-powered machines. Printing presses were powered by steam, and their efficiency made newspapers much more affordable in the penultimate decade of the 19th century. Even in the still many jobs done by hand, the tools used were often made using machines driven by steam. In short, any work that required pushing, pulling, lifting, or pressing could be made much more efficient using steam-powered machines. The star machine, and certainly the biggest, was the steam hammer.

In 1839, the steam hammer was invented by James Nasmyth (1808-1890). It was used to shape very large pieces of iron into such machine components as propellor shafts for shipping. The hammer worked with the steam power raising a large weight and then dropping it vertically on the metal to be bent. Crucially, the machine controlled the descent of the weight, both in terms of its speed and precision, which permitted a uniform production of shaped iron or steel. Later, steam power pushed the weight down, too, meaning just about any piece of metal of any size could be shaped. Steam hammers grew to a prodigious size, some were over 35 feet (10.6 metres) tall and weighed 90 tons which meant they created a massive amount of noise that could be heard across towns.

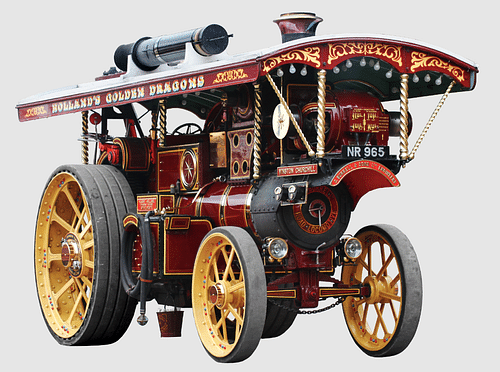

One of the great advantages of steam-powered engines was that they could be moved to wherever they were needed. This was particularly useful for agriculture and such contraptions as threshing machines. Steam engines could now look like a small train, but these were not transport vehicles; they were designed to allow steam power to reach anywhere it was required. Fairgrounds, which moved around the country, were another beneficiary of steam power, used to work mechanical rides. A distinct type of portable steam engine, the showman's engine, developed for these fairs, and they became highly decorated attractions in themselves.

Consequences

Steam power may have reduced production costs, made profits higher, and permitted mass-produced consumer goods to be cheaper, but these benefits came at a cost. Traditional industries like hand-weaving were all but destroyed by the arrival of steam-powered factories. Stagecoaches, mail coaches, coaching inns, and those who bred and cared for horses all suffered badly as trains took their business. Many people lost the livelihood they and their parents and grandparents had depended upon to live. Men, especially, lost their jobs as factory owners preferred to employ cheaper women and child labourers. Life became cramped in the cities, and the air was noticeably less clean.

Some people protested at the changes, particularly in the great manufacturing cities of Yorkshire, Lancashire, and Nottinghamshire. The period between 1811 and 1816 was particularly problematic for factory owners. Known as Luddites after their mythical leader Ned Ludd, the more violent protestors broke into factories and smashed the machines that had taken away their livelihoods. The Establishment fought back. Handsome rewards were offered for information on or for the capture of Luddites, and the army was called in to protect factories. Those protestors who were caught faced harsh penalties that included hanging or deportation to Australia.

The steam revolution caused job losses and upheaval for many, but it also created new jobs, too. Machinery allowed for larger factories, which called for a greater number of workers, and so more people began to live in towns and cities. Machines needed huge amounts of coal, and the new products they made needed more steel and iron, which resulted in more mines and more jobs. Machines permitted new possibilities in the use of metals, and so vast construction projects like tunnels, bridges, and railways brought more employment. The railways needed engineers, drivers, labourers, stationmasters, and porters. Shops flourished as urban workers had a little more money than before which they could spend on interesting goods from across the British Empire. Seaside resorts boomed thanks to train excursions. The centuries-old dominance of agriculture in Britain was coming to an end, and a whole new way of life was beginning for many.

There was another lasting consequence of steam power, machines, and the concentration of labour. Factories with heavy machinery were hot and noisy places, and workers had to work long hours. These poor conditions helped form the trade union movement, which sought to protect workers' rights from unscrupulous factory owners. Once unions were established they were able to collect funds from members and help those workers who were sick or injured and unable to work (and so were not paid). Owners did not like these limits on their profits, and the government banned trade unions between 1799 and 1824, but the movement to protect workers could not be stopped indefinitely.

Meanwhile, steam-powered machines kept on spreading into new areas, both geographical and industrial. Steam engines were built across the British Empire and elsewhere, spreading the innovation even to where coal was more expensive thanks to great leaps forward in fuel efficiency. Other countries soon caught up with Britain. The Industrial Revolution, driven by steam, had become an unstoppable and self-perpetuating global phenomenon.